Torq-Master

PRODUCT DESCRIPTION

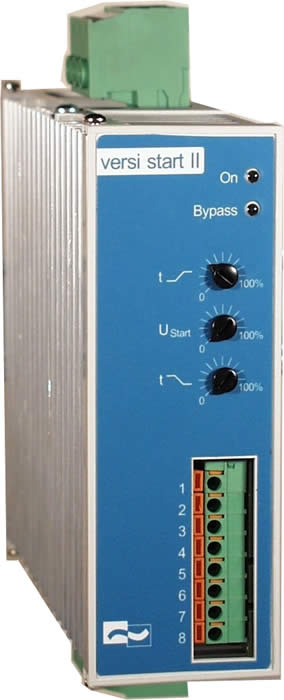

Solid State Soft Starters The TORQ-MASTER 2000 series

The TORQ-MASTER 2000 soft starter supplies a modern solution to motor starting by offering a controlled and step-less acceleration to full speed, eliminating the problems caused by current and torque transients. They also offer a soft stop or ramp down facility that is very beneficial in stopping water hammer in pumping systems.The TORQ-MASTER 2000 soft starter in its simplest form can be likened to a primary resistant starter in that it controls the voltage supplied to the motor by means of an impedance in series with each phase. The soft starter generally uses thyristors (SCR’s) instead of fixed or liquid resistors and the voltage is controlled by a variation of the SCR conduction angle. The SCR has a very low power dissipitation compared to traditional primary resistors during starting and is controllable to give motor voltage from zero or low voltage, to full line voltage without any steps or transients.

The TORQ-MASTER 2000 soft starter comes with two types of acceleration ramp :

- The open loop mode is the most common and simply ramps the motor to full speed by increasing the voltage from the PEDESTAL voltage to the TARGET voltage over an adjustable time period.

- The closed loop control commonly called current limiting or constant current monitors the current during the ramp process and limits the set value until the motor reaches full speed.

The entire range of RALSPEED soft starters are designed for use with by-pass contactors. The TQM2KB version has the bypass contactor built in and fully wired ready for customer connection. The TQM2K--\B version is set up with all connections provided for the user to install his own by-pass contactor.

By using the TORQ-MASTER 2000 soft starter it is possible to:

- Eliminate voltage flicker and line disturbance problems.

- Reduce excessive mechanical wear in chains, belts, gearboxes etc.

- Provide increased start capability through the reduction of mechanical wear and electrical stresses.

There are many additional features within the TORQ-MASTER 2000 soft starter such as electronic overload, load monitoring, data log, indicating and alarm functions, and control signals for interlocking.

It is possible to use Soft Starter with slip ring or wound rotor motors but it is important to establish the rotor amps and volts so that an appropriate torque increasing resistor can be supplied to enable the motor to have ‘starting torque’. This resistor should be shorted out when the motor reaches full speed.

Conditions to be determined when considering soft starting:

- Type of load i.e. high inertia, low inertia

- Duty Cycle Required

- Motor rating or full load current

- Ambient temperature

- Soft Starter housing required i.e. IP20 (chassis) or IP54 (enclosed)

- Supply voltage and frequency

- Additional features such as electronic overload, alarm contacts, signalling contacts etc.

The advantages of using an electronic Soft Starter can briefly be summarised as follows:

- The elimination of current transients

- The elimination of torque transients

- Extended life from mechanical drive systems

- Reduced stresses in the motor

- Possibility of electronic stopping and starting (leaving the contactor closed) where rapid switching is required.

- Reduced maintenance costs

- Avoidance of ‘crash’ starting fragile loads

- The ability to soft stop a motor as in pumping applications.