Thermography

is the leading non-intrusive, non-invasive and non-destructive

tool available for use in identifying faults within plant,

equipment and buildings. The technique is invaluable in being

able to identify faults before they actually give rise to an

unplanned and costly breakdown.

Thermography

is the leading non-intrusive, non-invasive and non-destructive

tool available for use in identifying faults within plant,

equipment and buildings. The technique is invaluable in being

able to identify faults before they actually give rise to an

unplanned and costly breakdown.

All objects

above -273�C or 0 Kelvin (absolute zero) emit infrared energy.

This energy can be visualised and analysed through the use of

infrared camera systems.

All plant or

equipment in the early or later stages of failure heats up. This

differential in temperature gives the professional thermographer

the ability to identify and investigate further whether a

genuine fault is developing or the temperature rise is a normal

effect.

Thermography

is the use of an infrared imaging and measurement camera to

"see" and "measure " thermal energy emitted from an object.

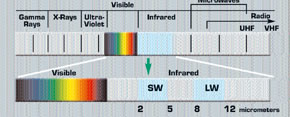

Thermal, or

infrared energy, is light that is not visible because its

wavelength is too long to be detected by the human eye; it's the

part of the electromagnetic spectrum that we perceive as heat.

Unlike visible light, in the infrared world, everything with a

temperature above absolute zero emits heat. Even very cold

objects, like ice cubes, emit infrared. The higher the object's

temperature, the greater the IR radiation emitted. Infrared

allows us to see what our eyes cannot.

Infrared

thermography cameras produce images of invisible infrared or

"heat" radiation and provide precise non-contact temperature

measurement capabilities.

"Nearly everything gets hot

before it fails, making infrared cameras extremely

cost-effective, valuable diagnostic tools in many diverse

applications."

Also as

industry strives to improve manufacturing efficiencies, manage

energy, improve product quality, and enhance worker safety, new

applications for infrared cameras continually emerge.

Defective connection to contactor

Extremely hot terminal

Faulty

connection to main isolator

Why

use it?

Many

commercial and industrial enterprises demand a high degree of

reliability and availability from their electrical

installations. Traditional forms of preventative maintenance are

very limited in their effectiveness in identifying substandard

electrical contact situations. In addition, preventative

maintenance requires the isolation of electrical equipment,

which is often inconvenient to processes and production.

Infrared Thermography provides a means of condition monitoring

live systems and detecting electrical faults during the early

stages of development through the generation of heat. Early

fault detection provides the time required to plan and carry out

the necessary repairs before catastrophic failure.

Typically, the faults most frequently detected are those

associated with terminations and connections. The mechanical

integrity of electrical connections may be affected in a variety

of ways (i.e. looseness, over-tightening, corrosion etc.).

The prime

difference between Infrared Thermography and cheaper more simply

applied forms of temperature measurement is that temperatures

can be observed and measured without having to make physical

contact.

With thermal imaging cameras, the temperature of surfaces within

the field of view, can be measured, recorded and analysed when

convenient, and for electrical applications, local maintenance

staff can be alerted immediately when potentially dangerous

situations are discovered.

Whilst this sounds straight forward, the considerable benefits

to be derived from its use, depend on selecting the correct

equipment and having the skill and knowledge to use it

effectively. For this, the user will require knowledge of the

operating principles of thermographic equipment, an

understanding of the physics and principles involved and a sound

technical background specific to the intended application.

For IR/T electrical inspection, the prime benefits are:

increased plant availability through a reduction in planned

downtime and a reduction in unplanned downtime through the

detection of faults prior to failure and the avoidance of

consequential damage.

Our thermographers will

identify a fault and propose remedial actions to rectify the

situation before it develops into a costly breakdown.